What are the key points to pay attention to in the daily operation of vibrating screens?

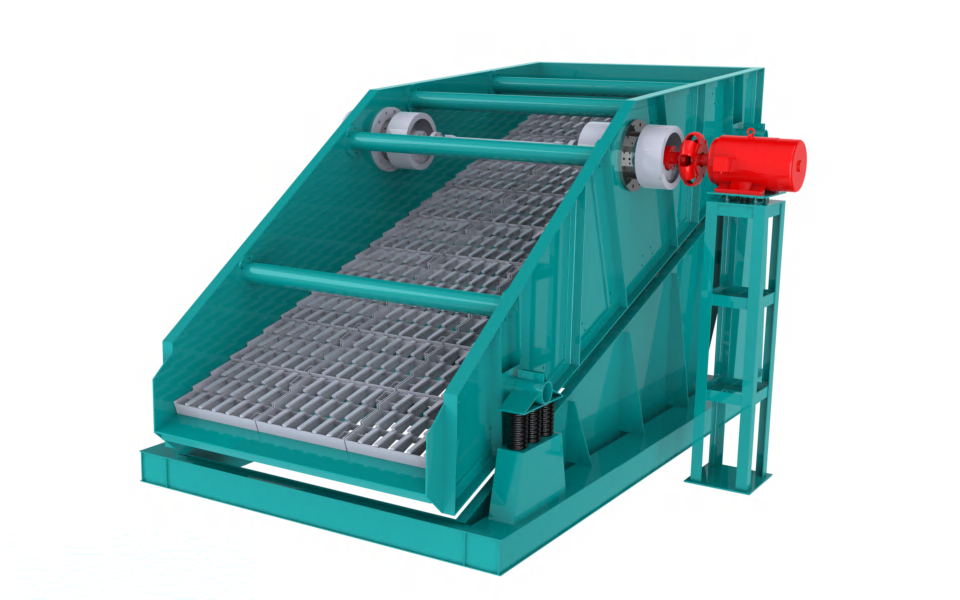

In mineral processing plants, vibrating screens mainly rely on their

vibration characteristics to complete classification, dewatering, and desliming

operations. Due to the complex working environment of the vibrating screen,

prolonged continuous operation and heavy loads, the vibrating screen will

inevitably suffer damage or even malfunction. To ensure the normal screening

operation of the beneficiation plant and extend the service life of the

vibrating screen, we need to use the vibrating screen correctly. So, what operational points should we pay attention to during the daily

operation and operation of the vibrating screen? Before starting the vibrating screen, conduct equipment inspection The operator of the vibrating screen should fully understand and be

familiar with the structure and working principle of each part of the vibrating

screen. Before starting the vibrating screen, the operator should prepare for

driving, check the condition of the drive belt or tire coupling, the integrity

of the screen mesh, and the condition of other parts and components. For

example, whether the connecting components such as screws are securely fastened,

whether electrical components have failed, whether the spindle of the vibrator

is flexible, and whether the bearing lubrication is good. 2. Correctly start and stop Vibration screens are commonly used in crushing and screening processes or

washing processes, and require no-load start-up and shutdown. Therefore,

operators need to follow the principle of starting in reverse process flow and

stopping in sequence with process flow. When starting the vibrating screen, it

is necessary to close the knife switch, connect the line to the power grid,

press the start button, and complete the start in one go. Except for special

accidents, it is not allowed to park the vibrating screen with materials. When

parking, press the parking button to complete. 3. Ensure proper lubrication of the vibrating screen The lubrication work of the vibrating screen mainly refers to the

lubrication of the vibrator bearings, transmission gears, and transmission

motors. The lubrication of vibrating screens is divided into two types: grease

lubrication and thin oil lubrication. For vibrators lubricated with grease,

high-quality lithium based grease with a temperature range of -30~120 ℃ should

be used. Under normal working conditions, each vibrator is generally oiled with

150-200g of grease within 24 hours. If the working environment of the vibrator

is harsh, it can also be oiled once every 8 hours, and it is recommended to use

a high-pressure grease gun for oiling. For vibrators and gears lubricated with

thin oil, high-quality gear oil can be used. When the ambient temperature is

less than 5 ° C, industrial gear oil No. 70 can be used; When the ambient

temperature exceeds 5 ° C, use industrial gear oil grade 90. The amount of fuel

added should depend on the structure of the vibrator. When the oil is added and

the oil level check rod is removed, a small amount of oil droplets continuously

drip out, which meets the requirements. For newly installed vibrating screens, the lubricating oil needs to be

replaced once after 80 hours of operation, and every 300 hours thereafter. In

winter and summer, due to significant temperature differences, it is recommended

to use lubricants with different viscosities. In addition, when injecting oil,

it is necessary to clean the nozzle and the area around the oil injection port

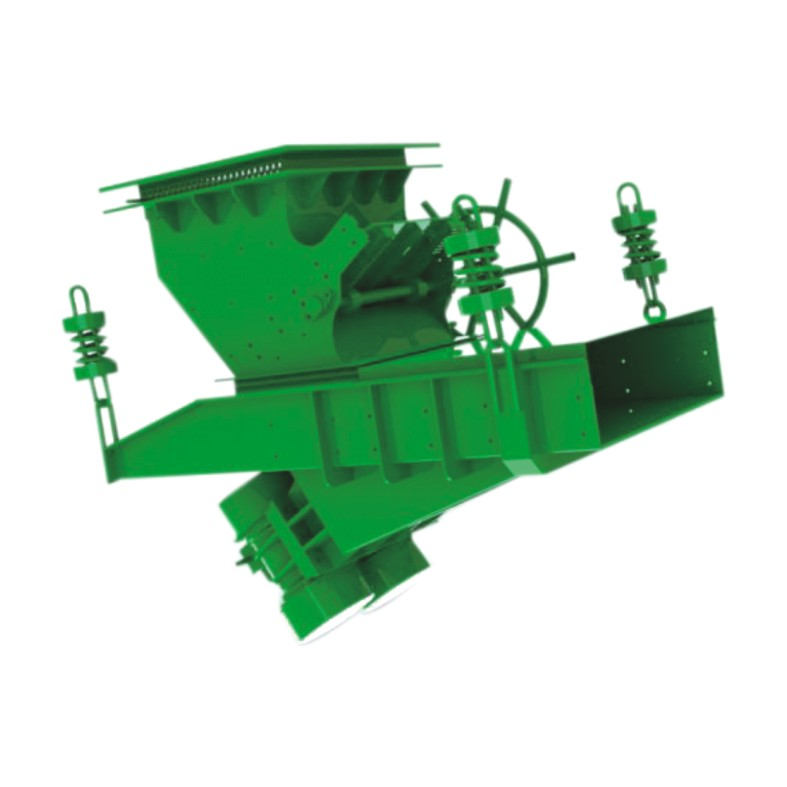

to prevent dust from entering the oil chamber. 4. Clarify the rotation direction of the vibrator For a circular vibrating screen, the rotation direction of the vibrator can

be either in the direction of the material flow or against the direction of the

material flow. When rotating in the direction of the material flow, the material

passes through the screen surface at a faster speed, which is beneficial for

improving the processing capacity of the circular vibrating screen; When the

material rotates in the opposite direction of the material flow, the speed of

the material passing through the screen surface is slow, and the material is

prone to blockage. At this time, it is necessary to increase the inclination

angle of the screen surface appropriately. For a self synchronous linear

vibrating screen, the two eccentric masses are generally driven by two motors,

and the characteristics of the two motors must be the same, while the rotation

direction must be opposite. For asynchronous linear vibrating screens, there is

no clear regulation on the direction of rotation. 5. Adjust the amplitude of the vibrating screen in a timely manner During the production process, if the operator finds that the amplitude of

the vibrating screen cannot meet the requirements of the screening operation,

they can adjust its amplitude in a timely manner. For example, if the vibrating

screen uses a block eccentric vibrator, the operator can adjust the angle

between the main and auxiliary eccentric blocks. The angle decreases, the

excitation force increases, and the amplitude increases; On the contrary, as the

angle increases, the excitation force decreases and the amplitude decreases. If

the vibrating screen adopts a shaft eccentric vibrator, the operator can

increase or decrease the counterweight on the flywheel and pulley to increase or

decrease the amplitude of the vibrating screen.