威达机械

集研发、设计、生产、销售一站式服务

One stop service for research and development, design, production, and sales 在线咨询 >

quick response

Free customization

Worry free service

PRODUCT DETAILS

Product details introduction:

The LS type screw conveyor has a diameter ranging from 100mm to 1250mm, with a total of twelve specifications, divided into two forms: single drive and double drive. The maximum length of the single drive screw machine can reach 40m (extra large 30m), while the double drive screw machine adopts a middle disconnect shaft structure, with a maximum length of 80m (extra large 60m). The length of the screw machine is adjusted every 0.5 meters, and can be selected according to needs. The head and tail bearings of the screw machine are placed outside the housing to reduce dust intrusion into the bearing chamber and improve the service life of the screw key components. The intermediate suspension bearing adopts two interchangeable structures of rolling and sliding, with low resistance, strong sealing, and good wear resistance. The bearing shells of sliding bearings are made of various materials such as powder metallurgy, nylon, and Babbitt alloy for users to choose according to different working conditions. The outer side of the suspension bearing machine is equipped with an oil cup, which is convenient for centralized refueling and lubrication. The layout of the inlet and outlet positions is flexible, and an electric discharge outlet is added for automatic control. Speed measurement alarm devices can also be configured according to user requirements.

Product features and application scope:

The LS type screw conveyor has a diameter ranging from 100mm to 1250mm, with a total of twelve specifications, divided into two forms: single drive and double drive. The single drive screw machine can reach a maximum length of 40m (extra large 30m), while the double drive screw machine adopts a middle disconnect shaft structure, with a maximum length of 80m (extra large 60m). The length of the screw machine can be selected in increments of 0.5 meters according to needs. The head and tail bearings of the screw machine are placed outside the housing to reduce dust intrusion into the bearing chamber and improve the service life of the key components of the screw mechanism. The intermediate suspension bearing adopts two interchangeable structures of rolling and sliding, with low resistance, strong sealing, and good wear resistance. The bearing shells of sliding bearings are made of various materials such as powder metallurgy, nylon, and Babbitt alloy for users to choose according to different working conditions. The outer side of the suspension bearing machine is equipped with an oil cup, which is convenient for centralized refueling and lubrication. The layout of the inlet and outlet positions is flexible, and an electric discharge outlet is added for automatic control. Speed measurement alarm devices can also be configured according to user requirements.

Screw machines have been widely used in the building materials, metallurgy, chemical, power, coal, machinery, light industry, grain and food industries, suitable for conveying powdery, granular, and small block materials such as cement, coal, grain, fertilizers, ash, sand, coke, etc. It is not suitable to transport logistics that are prone to spoilage, high viscosity, and clumping. The working environment temperature of LS screw conveyor is -20 ℃ -40 ℃, and the temperature of conveyed materials is generally -20 ° -80 ℃. LS screw conveyor is suitable for horizontal and small inclination arrangement, and the inclination angle should not exceed 15 ℃. Special design and manufacturing can be carried out.

2、 Model specifications and technical parameters (see Table 1)

The LS type screw conveyor is divided into small, medium, large, and extra large sizes, with a total of twelve specifications.

| Model specifications | Spiral diameter mm | Pitch mm | rotational speed r/min | Conveying capacity m³/h | rotational speed r/min | Conveying capacity m³/h | rotational speed | Conveying capacity | rotational speed r/min | Conveying capacity | |

| r/min | m³/h | m³/h | |||||||||

| S | n | φ=0.33 | n | φ=0.33 | n | φ=0.33 | n | φ=0.33 | |||

| small-scale | LS100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| LS125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| LS160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| LS200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| medium-sized | LS250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| LS315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| LS400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| large | LS500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| LS630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| LS800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

| Extra Large | LS1000 | 1000 | 560 | 32 | 277.9 | 25 | 217.1 | 20 | 173.7 | 16 | 139 |

| LS1250 | 1250 | 630 | 25 | 381.7 | 20 | 305.4 | 16 | 244.3 | 13 | 198.5 |

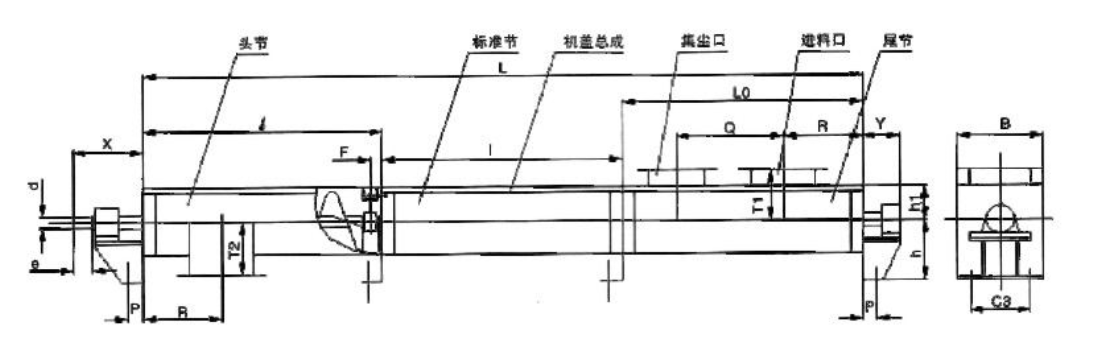

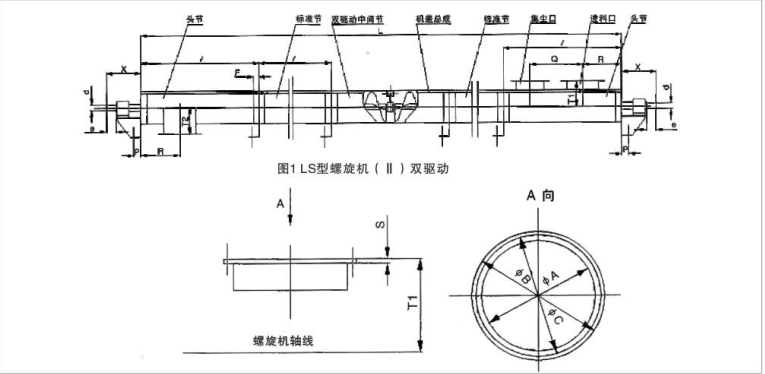

3. Appearance and installation dimensions:

The assembly diagram of LS type screw conveyor is shown in Figure 1 and Figure 2, and the small-sized machines (LS100, LS200) do not have a dual drive form;

Figure 1 LS type spiral machine (I) single drive

The corresponding dimensions are shown in Table 2. The LO size in the table is set every 500mm.

| model | h | h1 | l | C3 | B | F | L0 | P | Q | R | T1 | T2 | X | Y | d | e |

| LS100 | 140 | 63 | 2500 | 100 | 180 | 50 | 1000~3000 | 60 | 1000 | 190 | 120 | 110 | 232 | 170 | 25 | 42 |

| LS125 | 160 | 75 | 2500 | 130 | 210 | 50 | 1000~3000 | 60 | 1000 | 220 | 130 | 130 | 252 | 170 | 30 | 58 |

| LS160 | 180 | 90 | 2500 | 160 | 244 | 50 | 1000~3000 | 60 | 1000 | 250 | 150 | 150 | 254 | 176 | 35 | 58 |

| LS200 | 200 | 112 | 2500 | 200 | 304 | 50 | 1000~3000 | 60 | 1000 | 285 | 180 | 180 | 285 | 182 | 40 | 82 |

| LS250 | 250 | 140 | 3000 | 250 | 356 | 50 | 1000~3500 | 60 | 1000 | 330 | 210 | 220 | 292 | 188 | 50 | 82 |

| LS315 | 280 | 180 | 3000 | 320 | 420 | 100 | 1000~3500 | 60 | 1000 | 380 | 250 | 250 | 322 | 190 | 60 | 105 |

| LS400 | 355 | 224 | 3000 | 400 | 530 | 100 | 1000~3500 | 60 | 1000 | 430 | 300 | 280 | 406 | 212 | 70 | 140 |

| LS500 | 400 | 280 | 4000 | 500 | 632 | 100 | 1500~5000 | 100 | 1000 | 500 | 360 | 340 | 441 | 218 | 80 | 170 |

| LS630 | 500 | 355 | 4000 | 630 | 768 | 150 | 1500~5000 | 100 | 1000 | 570 | 430 | 420 | 528 | 240 | 100 | 210 |

| LS800 | 630 | 450 | 4000 | 800 | 998 | 150 | 1500~5000 | 100 | 1000 | 710 | 530 | 520 | 542 | 260 | 120 | 210 |

| LS1000 | 710 | 560 | 4500 | 1000 | 1212 | 200 | 1500~5500 | 100 | 1000 | 810 | 640 | 630 | 616 | 272 | 140 | 250 |

| LS1250 | 800 | 710 | 4500 | 1250 | 1462 | 200 | 1500`5500 | 100 | 1000 | 1000 | 880 | 760 | 671 | 284 | 170 | 300 |

Note: The size R is the minimum size for the feed inlet; The size Q is the minimum size.

Figure 2LS Spiral Machine (II) (Dual Drive)

Length and combination (see Table 3)

| Model specifications | scolex | telson | A-type dual drive | B-type dual drive | ||||||||||

| Standard section I | L0 | Intermediate section | Intermediate section | |||||||||||

| small-scale | LS100~LS200 | 2.5 | 1 | 1.5 | 2 | 2.5 | 3 | |||||||

| medium-sized | LS250~LS400 | 3 | 1 | 1.5 | 2 | 2.5 | 3 | 3.5 | L0 | I+L0 | ||||

| large | LS500~LS800 | 4 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | ||||

| Extra Large | LS1000~LS1250 | 4.5 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 5 | (See the end section) | (See the beginning and end section) | |

The length of a single drive screw machine (every 0.5m) is L=n1+L0 (n1), and its combination is: 1 head section+(n-1) standard section+1 tail section

Double drive screw machine length (every 0.5m) (1) adopts A-type double drive intermediate section: L=21+L0 (2) adopts B-type double drive intermediate section: L=2n+(1+L0)

Its combination is: 2 head joints+2 (n-1) standard joints+1A (B) type dual drive middle

Our advantages

Related products